Montreal Based Company | A Leader in Automated Quality Control Software

For companies in regulated industries, strict labelling and packaging requirements must be adhered to at all times. Failure to comply with these regulations can result in many issues like market delays, complaints, and even recalls.

Despite entire quality control departments dedicated to proofreading labels and packaging components, there are many factors that can contribute to letting an error slip by unnoticed. Manual proofreading can be slow, inefficient, and prone to human error, especially when there are multiple product lines and hundreds of SKUs to manage. Automated quality control software, like GlobalVision, helps businesses stop critical errors while eliminating the inefficiencies that come with manual proofreading, so they can get products to market faster without compromising quality.

What is GlobalVision?

GlobalVision is the leading provider of document inspection software for companies in regulated industries. Committed to helping businesses get assets developed faster and more accurately, GlobalVision serves more than 800 companies ranging from the world’s largest pharmaceutical and consumer goods companies to quality-focused print and packaging companies and marketing and advertising agencies. Businesses across all market segments choose GlobalVision to ensure error-free content at every stage of their unique workflows.

GlobalVision is the leading provider of document inspection software for companies in regulated industries. Committed to helping businesses get assets developed faster and more accurately, GlobalVision serves more than 800 companies ranging from the world’s largest pharmaceutical and consumer goods companies to quality-focused print and packaging companies and marketing and advertising agencies. Businesses across all market segments choose GlobalVision to ensure error-free content at every stage of their unique workflows.

What are the challenges associated with manual proofreading?

No matter the industry, error-free packaging is essential for a number of reasons. Aside from the legal and financial implications of having to reprint or recall packaging, even the smallest mishap can lead to consumers losing trust in your brand and thus turning towards a competitor. GlobalVision’s digital inspection software automates quality control to reduce the risk of unwanted changes from making it to market. In turn, companies can release their products with confidence knowing that their consumers, and brand equity, are safe.

No matter the industry, error-free packaging is essential for a number of reasons. Aside from the legal and financial implications of having to reprint or recall packaging, even the smallest mishap can lead to consumers losing trust in your brand and thus turning towards a competitor. GlobalVision’s digital inspection software automates quality control to reduce the risk of unwanted changes from making it to market. In turn, companies can release their products with confidence knowing that their consumers, and brand equity, are safe.

As product lines expand and companies move their products into foreign markets, the speed at which companies get products onto shelves is becoming more important, especially in such competitive landscapes. With manual proofreading, long delays caused by quality control issues are common. For example, printing companies oftentimes have to stop the press machines for hours at a time if a misprint or defect is detected while proofs are being printed. For pharmaceutical companies, a small spelling error on a document or leaflet can significantly delay the process of getting products out the door while additional quality control checks are conducted.

From a financial perspective, any label or packaging defect can cost a company thousands of dollars in wasted materials, labor, and additional resources as they end up with entire batches of unsellable inventory. To minimize the risk of costly recalls and errors, more and more companies are turning towards automated quality control.

Automatically detect all types of defects with GlobalVision’s inspection applications

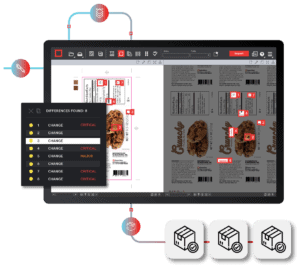

With inspection applications designed for use across multiple workflows, departments, and industries, GlobalVision’s software can detect several types of defects ranging from text errors, graphic and artwork defects, print errors, and more.

Text Inspection

With GlobalVision Text Inspection, users can instantly compare Word documents to PDFs to automatically verify all text and spelling. By running character to character inspections of each Unicode value, users can ensure that there are no unintended changes as work moves from copy documents to artwork files.

Graphics Inspection

GlobalVision Graphics Inspection ensures the integrity of artwork files as they move throughout workflows. The software works by overlaying two files to detect even the smallest differences with pixel-to-pixel precision. Examples of errors that can be detected include missing logos, color differences, misregistration, and more.

Barcode Inspection

With GlobalVision Barcode Inspection, users can digitally verify and grade barcodes without the use of a handheld scanner. By breaking down each barcode by its individual parameters, the software automatically displays the decoded value of each barcode. This protects packaging from faulty barcodes while also saving time by verifying them directly within the electronic file.

Print Inspection

GlobalVision Print Inspection compares hardcopy samples to digital files for fast and accurate offline inspections. The system works by enabling users to scan in printed proofs using GlobalVision-certified scanners that can be compared against approved electronic artwork files. With Print Inspection, users can detect errors on all types of printed packaging components in seconds.

Industries Served

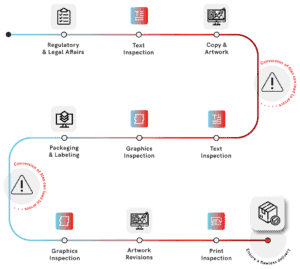

GlobalVision’s quality inspection software helps meet market standards by protecting work from critical errors at each stage of the workflow. For brand companies, like pharmaceutical and consumer goods, GlobalVision is used along the quality control process to ensure that work is 100% accurate before going to market. The software helps keep track of version changes between departments from regulatory affairs to incoming quality control while allowing users to compare approved files to incoming supplier proofs. This helps minimize the risk of customer complaints and recalls while dramatically reducing inspection time compared to manual proofreading.

GlobalVision’s quality inspection software helps meet market standards by protecting work from critical errors at each stage of the workflow. For brand companies, like pharmaceutical and consumer goods, GlobalVision is used along the quality control process to ensure that work is 100% accurate before going to market. The software helps keep track of version changes between departments from regulatory affairs to incoming quality control while allowing users to compare approved files to incoming supplier proofs. This helps minimize the risk of customer complaints and recalls while dramatically reducing inspection time compared to manual proofreading.

On the supplier side, GlobalVision helps printers and creative agencies complete jobs accurately and on time by catching all inconsistencies between sample files and customer-approved documents. Starting with file creation and ending in final production, GlobalVision’s quality control tools enable seamless inspections that detect all differences while maximizing productivity gains. Additional benefits for brand and supplier companies include:

- Secure and verified inspection technology that helps set your business apart from the competition.

- Minimized financial risk by reducing the number of reworks, wasted materials, and additional labor required to correct errors.

- The ability to keep projects within time constraints allows businesses to focus more resources on additional projects.

Getting started with GlobalVision

GlobalVision’s automated quality control tools are becoming increasingly implemented across workflows to help businesses effectively manage quality control on labels and packaging. If you’ve been looking for ways to improve the efficiency of your inspection process, see how GlobalVision can help by requesting a demo here.

Original article here: https://blog.globalvision.co/company/what-is-globalvision-how-to-instantly-catch-errors-with-automated-quality-control-software/